Patent Backed Bankruptcy Report

Company Background:

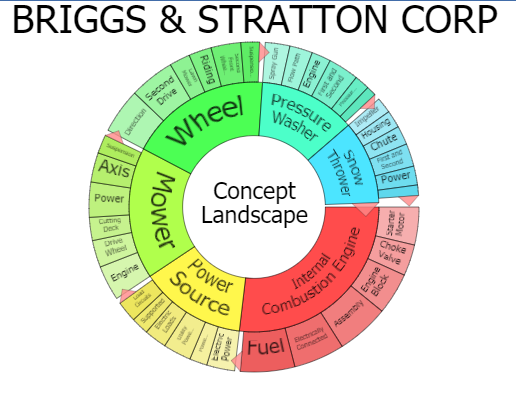

Briggs & Stratton Corporation is a producer of gasoline engines for outdoor power equipment. The Company designs, manufactures, markets, sells and services the various products for original equipment manufacturers (OEMs) around the world. It also markets and sells related service parts and accessories for its engines. Its subsidiary is a marketer of pressure washers, and it is a designer, manufacturer and marketer of power generation, lawn and garden, turf care and job site products through its Simplicity, Snapper, Snapper Pro, Ferris, PowerBoss, Allmand, Billy Goat, Murray, Branco and Victa brands. It operates in over 100 countries on six continents. It operates through two segments: Engines and Products. Its Engines segment sells engines around the world, primarily to OEMs of lawn and garden equipment and other gasoline engine-powered equipment. Its Products segment designs, manufactures and markets a range of outdoor power equipment, job site products and related accessories.

Address

Ownership

Industry

12301 W. Wirth Street

Wauwatosa, WI 53222

Public (BGG)

Industrial Manufacturing and Service

Consumer Product Manufacturing

Chapter Type | Case Number | Assets | Liabilities | Industry/Description |

11 | 4:2020bk43599 | 500M – 10,000M | 500M – 7,500M | Industrial Manufacturing and Services Consumer Product Manufacturing |

Portfolio Valuation Range | Asset Valuation Range | Total Assets Valuation Range | Liability Range | Leverage Ratio Range |

$4.250M – $17M | $500M – $10,000M | $504.25M – $10,017M | $500M – $7,500M | 0.06723 – 20.034 |

Patent Portfolio Breakdown

102 Total Assets

- 170 Active US Patents

- 111 Foreign Counterparts

Featured Assets

Abstract:

An internal

combustion engine includes an engine block including a cylinder, a piston

positioned within the cylinder, a crankshaft configured to be driven by the

piston, a fuel system for supplying an air-fuel mixture to the cylinder, a

starter motor, and a lithium-ion battery mounted on the engine, the lithium-ion

battery configured to power the starter motor to start the engine, wherein the

piston is configured to reciprocate in the cylinder along a cylinder axis,

wherein the lithium-ion battery includes at least one lithium-ion cell having a

longitudinal cell axis, and wherein the cylinder axis and the longitudinal cell

axis are not parallel to one another.

Claim 1:

1. An internal combustion engine, comprising:

an engine block including a cylinder;

a piston positioned within the cylinder;

a crankshaft configured to be driven by the piston;

a fuel system for supplying an air-fuel mixture to the cylinder;

a starter motor; and

a lithium-ion battery mounted on the engine, the lithium-ion battery configured

to power the starter motor to start the engine.

Abstract:

An

engine including an automatic choke that includes a choke valve movable between

a fully closed position and a fully open position, a temperature sensor coupled

to the engine and operable to provide a temperature signal indicative of a

temperature of the engine, and a motor connected to the choke valve and

operable to move the choke valve in response to a motor control signal. A

controller is electrically connected to the motor and to the temperature

sensor. The controller includes an electronic circuit having a memory. A table

includes engine specific choke position data stored in memory, wherein the

controller determines a choke initial position based on the temperature of the

engine and the choke position data, and wherein the motor moves the choke valve

toward that position in response to an attempt to start the engine.

Claim 1:

1. An engine having an ignition system that generates an ignition signal, a piston, a rotating shaft that rotates in response to movement of the piston, and an automatic choke, the automatic choke comprising:

a choke valve movable between a fully closed position and a fully open position;

a motor connected to the choke valve and operable to move the choke valve in response to a motor control signal;

a temperature sensor coupled to the engine and operable to provide a temperature signal indicative of a temperature of the engine; and

a controller electrically connected to the motor and to the temperature sensor, the controller operable to control the choke valve for providing choke relief to the engine in at least two phases during a starting operation of the engine, wherein a first relief phase duration is based on a passage of a predetermined length of time and the duration of a second relief phase is based on a passage of a predetermined number of revolutions of the engine.

Abstract

A method for cooling a generator. The method includes drawing air into a first

zone of a housing through a first air intake, drawing air through a controller

air intake adjacent a generator controller, directing air from the first zone

into a second zone past a separator, drawing air into the second zone from both

the first zone and the controller air intake, and exhausting air from the

second zone to the exterior of the generator.

Claim 1:

1. A cooling system for a generator, the cooling system comprising:

a housing having a first zone and a second zone at least partially divided by a

separator, the first zone comprising:

an engine;

a first fan rotatable by a crankshaft;

a first air intake; and

wherein substantially all air from the first zone is directed to the second zone;

the second zone comprising:

an alternator;

a second fan;

a second air intake; and

wherein substantially all air from the second zone is directed to the exterior of the

generator;

a controller; and

an exhaust duct adjacent a muffler.

.