[vc_row][vc_column][vc_column_text]Continental Commercial Products, LLC provides floor care, janitorial, and food service cleaning products to janitorial and sanitation, food service, healthcare, institutional and schools, building service, contractors, industrial, and retail markets. Continental Commercial Products, LLC was formerly known as Contico International, L.L.C. and changed its name to Continental Commercial Products, LLC in June 2003. The company was founded in 1939 and is based in Bridgeton, Missouri with subsidiaries and/or affiliates in the United States and Canada. Continental Commercial Products, LLC operates as a subsidiary of Katy Industries, Inc.

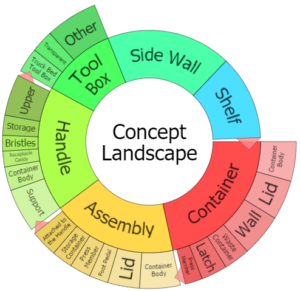

Katy Industries, Inc. is a manufacturer, importer and distributor of commercial cleaning and consumer storage products, as well as a contract manufacturer of structural foam products. The Company’s subsidiary is Continental Commercial Products, LLC, which includes four business units: Continental, Wilen, Contico and Fort Wayne Plastics. The Continental business unit is a plastics manufacturer and an importer and distributor of products for the commercial janitorial/sanitary maintenance, industrial and foodservice markets. The Wilen business unit is a manufacturer, importer and distributor of cleaning products that include mops, brooms and sweeps, poles and handles, microfiber, brushes and plastic cleaning accessories. The Contico business unit is a plastics manufacturer and distributor of garage, shelving, tool and other home storage products. The Fort Wayne Plastics business unit is a contract manufacturer for various original equipment manufacturers.

Katy Industries filed Chapter 11 petitions as part of a reorganization to facilitate the sale of its assets and those of its subsidiaries.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_tta_tabs][vc_tta_section title=”Company Info” tab_id=”1485966886423-b3803678-c7ec5ac5-4518fd03-b29a”][vc_column_text]

|

Address 305 Rock Industrial Park Dr Bridgeton, MO 63044 United States

|

Ownership

Private Industry Plastic Materials and Synthetic Resins

|

[/vc_column_text][/vc_tta_section][vc_tta_section title=”Patent-Backed Value Estimation ” tab_id=”1485966886486-c8105d58-76bb5ac5-4518fd03-b29a”][vc_column_text]Katy Industries Debt-Asset Leverage Estimate

| Chapter Type | Case Number | Assets | Liabilities | Industry/Description |

| 11 | 17-11101 | $50-1000 Million | $50 – 100 Million | Plastic Materials and Synthetic Resins |

| Portfolio Valuation Range | Asset Valuation Range | Total Assets Valuation Range | Liability Range | Leverage Ratio Range |

| $900,000.00 – $3,950,000.00 | $25,000,000.00 – $100,000,000.00 | $25,900,000.00 – $103,950,000.00 | $5,000,000.00 – $25,000,000.00 | 1.036 – 20.79 |

Patent Portfolio

35 Total Assets

|

|

[/vc_column_text][/vc_tta_section][vc_tta_section title=”Featured Assets” tab_id=”1485967825251-b275f45c-d8b55ac5-4518fd03-b29a”][vc_column_text]Katy Industries Portfolio Summary

1. US7530139 B2

Title: Microfiber cleaning apparatus with cleaning pad removal feature

Abstract: A cleaning apparatus is comprised of an elongate handle and a cleaning head at one end of the handle. The cleaning head includes a pair of panels that can be moved relative to each other. The panels support a micro fiber cleaning pad. The cleaning pad can be released from the panels after use without manually touching the pad, thereby enabling disposal of a contaminated cleaning pad while reducing the potential for cross contamination to a user of the apparatus.

First Claim:

A cleaning apparatus comprising:

a lower panel having opposite top and bottom surfaces;

an upper panel having opposite top and bottom surfaces;

a connection mechanism between the lower panel and the upper panel that enables relative movement between the upper panel and the lower panel whereby the upper panel moves between first and second positions of the upper panel relative to the lower panel, where in the first position the upper panel bottom surface is positioned adjacent to the lower panel top surface and in the second position the upper panel bottom surface is moved away from the lower panel top surface;

a cleaning pad having opposite top and bottom surfaces;

and, a connector assembly between the cleaning pad top surface and the upper panel bottom surface that releasably connects the cleaning pad to the upper panel when the cleaning pad top surface is positioned adjacent to the lower panel bottom surface and the upper panel is in the first position, and that disconnects the cleaning pad from the upper panel when the upper panel is moved to the second position.

2. US6389638 B1

Title: Container assembly

Abstract: A container assembly includes a one piece container body and a press member connected to the container body. The container body includes a bottom wall and a plurality of side walls extending upwardly from the bottom wall to define a liquid reservoir. One of the side walls includes a wringing surface. The press member is operatively connected to the container body for movement of the press member between a wringing position and a non-wringing position relative to the wringing surface of the container body. The press member and the wringing surface define a mop receiving volume. The mop receiving volume has a volume V1 when the press member is in its non-wringing position and a V2 when the press member is in its wringing position. The volume V2 is less than the volume V1. The press member and the wringing surface are configured to wring liquid out of a mop upon movement of the press member from its non-wringing position toward its wringing position when a mop head is positioned between the press member and wringing surface.

First Claim:

A container assembly comprising:

a container body having an interior surface that defines a liquid reservoir; and

a wringing mechanism adjacent the liquid reservoir, the wringing mechanism including a wringing surface and a press member, the press member being operatively connected to the container assembly for movement of the press member between a wringing position and a non-wringing position relative to the wringing surface, the press member and the wringing surface being configured to wring liquid out of a mop upon movement of the press member from its non-wringing position toward its wringing position when a mop head is positioned between the press member and the wringing surface, the wringing surface and at least a portion of the container body being of a monolithic construction.

3. US7530578 B2

Title: Step-on receptacle with tip prevention

Abstract: A novel construction of a stabilized receptacle is provided in which the receptacle is comprised of only seven separate component parts that are assembled together without the use of separate threaded fasteners. In addition, the receptacle is provided with a stabilizing hoop that extends forwardly from the receptacle around the foot pedal of the receptacle and stabilizes the receptacle, preventing movement of the receptacle when the foot pedal is depressed.

First Claim:

A stabilized receptacle comprising:

a receptacle housing having a bottom wall and at least one sidewall extending upwardly from the bottom wall to a top edge of the sidewall, the receptacle having an interior volume and a top opening to the interior volume;

a lid attached to the housing for movement of the lid between a closed position of the lid where the lid is positioned over the housing top opening and a opened position of the lid where the lid is displaced from the housing top opening;

a foot pedal attached to the housing for movement of the foot pedal between a lid closed position and a lid opened position of the food pedal relative to the housing;

the foot pedal being operatively connected to the lid to cause the lid to move to the lid opened position in response to the foot pedal being moved to the lid opened position, and to cause the lid to move to the lid closed position in response to the foot pedal being moved to the lid closed position, the foot pedal having an end that projects outwardly from the receptacle;

a stabilizing hoop having opposite ends attached to the housing, the hoop having a length between the opposite hoop ends that extends outwardly from the housing and around the foot pedal end;

and, the opposite hoop ends being attached to the housing for pivoting movement of the hoop length between an extended position of the hoop where the hoop extends outwardly from the housing and around the foot pedal end, and a retracted position of the hoop where the hoop length is positioned beneath the housing bottom wall.

[/vc_column_text][/vc_tta_section][/vc_tta_tabs][/vc_column][/vc_row][vc_row][vc_column][vc_cta h2=”Portfolio Valuation ” h4=”IPVal offers portfolio valuation services.” add_button=”right” btn_title=”Contact Us ” btn_add_icon=”true” btn_link=”url:http%3A%2F%2Fipval.com%2Fcontact-us%2F%231467647561464-2a34809f-529c||”][/vc_cta][/vc_column][/vc_row][vc_row][vc_column][/vc_column][/vc_row]